Presentation

The I.C.P. - Industrial Cathodic Protection s.r.l., constituted in 1971, carries out its activity exclusively in the Cathodic Protection field and it is one of the few companies in Europe which plan and realize plants both at impressed current and "sacrificial anodes".

In both cases, the materials are of our production, because our company has an electric works (for transformer/rectifiers and accessories assembling in general) and a foundry for the realization of any type of alloy (Magnesium, Aluminium and Zinc).

Our company, with a long presence on the market, has acquired a considerable experience in the cathodic protection field, supplying plants to use in a great number of industrial installations, such as:

platforms, sealines, piers, underground pipelines, underground tanks, stocking tanks, heat exchangers, hulls

Design

I.C.P. s.r.l. has got an highly skilled staff of technicians that are able to design every type of cathodic protection system for undergrounded metallic structures, in sea water, in fresh water, in concrete and in particularly aggressive electrolytes.

Our company is able to carry out preliminary studies to provide technically valid projects, in the lead and economically advantageous.

This is possible thanks to the use of last generation instruments with useful characteristics able to supply the most important basic data for every circumstance.

The research that usually is conducted in order to eliminate or to avoid corrosion phenomenon can be summarized as follows:

preliminary

general information concerning the system

knowledge of materials used

presence of corrosive substances

environment analysis

presence of mechanical stress

on site tests

measures of resistivity

measure of the electrolyte's acidity degree

determination of the electric state

ON-OFF tests

research of faults in the coating with DCVG method

Our activity is carried out duly in compliance with the main international standards: UNI, CEI, BS, DIN, NF and NACE (NACE Member N° 125452-01).

Scarifical Anodes

The production of sacrificial anodes concerns exclusively the realization of Aluminum, Magnesium and Zinc anodic alloys.

These alloys are able to satisfy all the electrochemical requirements, with the result to grant the protection of the metallic structures to which the anodes is connected.

Besides I.C.P. s.r.l. is equipped with chemical laboratory complete of computerized spectrometer and electrolytic tanks for the evaluation of the anodic capacity.

In compliance with the DNV-RP-B401 provisions and as a completion of each supply, together with the materials are also issued the certificates concerning the tests made on the production casting moulds.

In case of anodes dimensional standards do not satisfy the customer's requirements, I.C.P. s.r.l. is able to realize suitable moulds conform to the requests

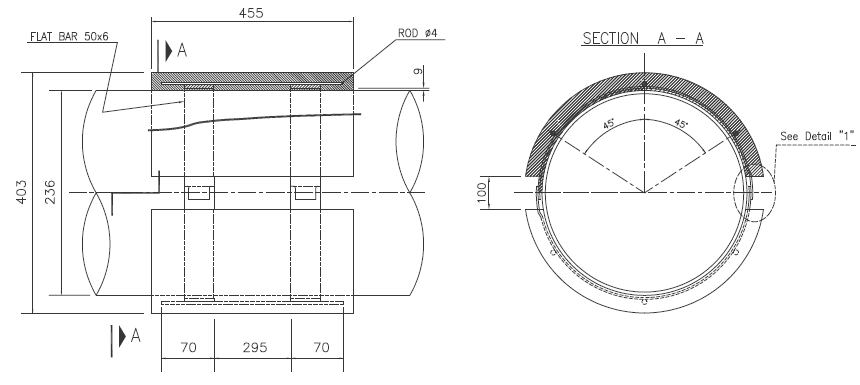

Structural Anodes

Chemical Laboratory

Magnesium anodes

Spectrometer

Impressed Current

I.C.P. s.r.l. measures and assembles every type of transformer rectifier from 2 to 1000 Ampere.

Our electric works produces the following type of transformer rectifiers: single-phase or three-phase, manual or automatic, air cooled or oil cooled, with protection degree from IP44 to IP65 or flameproof, wall fixing or floor fixing, assembled in steel painted box, in INOX or in fibreglass.

The standards that usually are ready in our factory cover a range that change from 5 to 20 Ampere for the air cooled type, and from 20 to 1000 Ampere for the oil cooled type.

Therefore our versatility allows us to realize, in short time, every type of transformer rectifier in compliance with the customer specifications.

Modular Transformer/rectifier

Oil cooled Transformer/rectifier

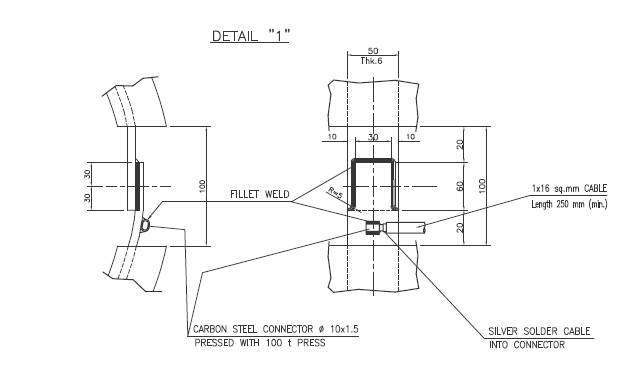

Cu/CuSo4 permanent type

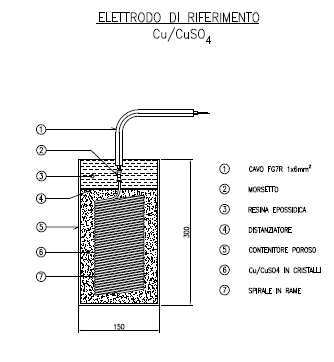

Thanks to the high consumption, in our factory are always available, in various size, anodes in Fe/Si/Cr, normal or in pre-packed version.

Besides we are able to rapidly supply many kind of Activated MMO Titanium anodes and/or platinized both for the sea water and ground use.

I.C.P. s.r.l. produces every type of reference electrodes (Cu/CuSO4, Ag/AgCl, High Purity Zinc and Titanium) both in portable and permanent version.

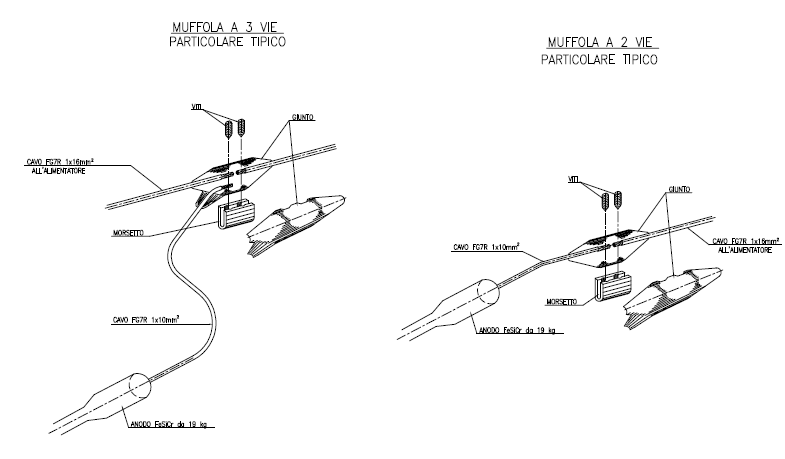

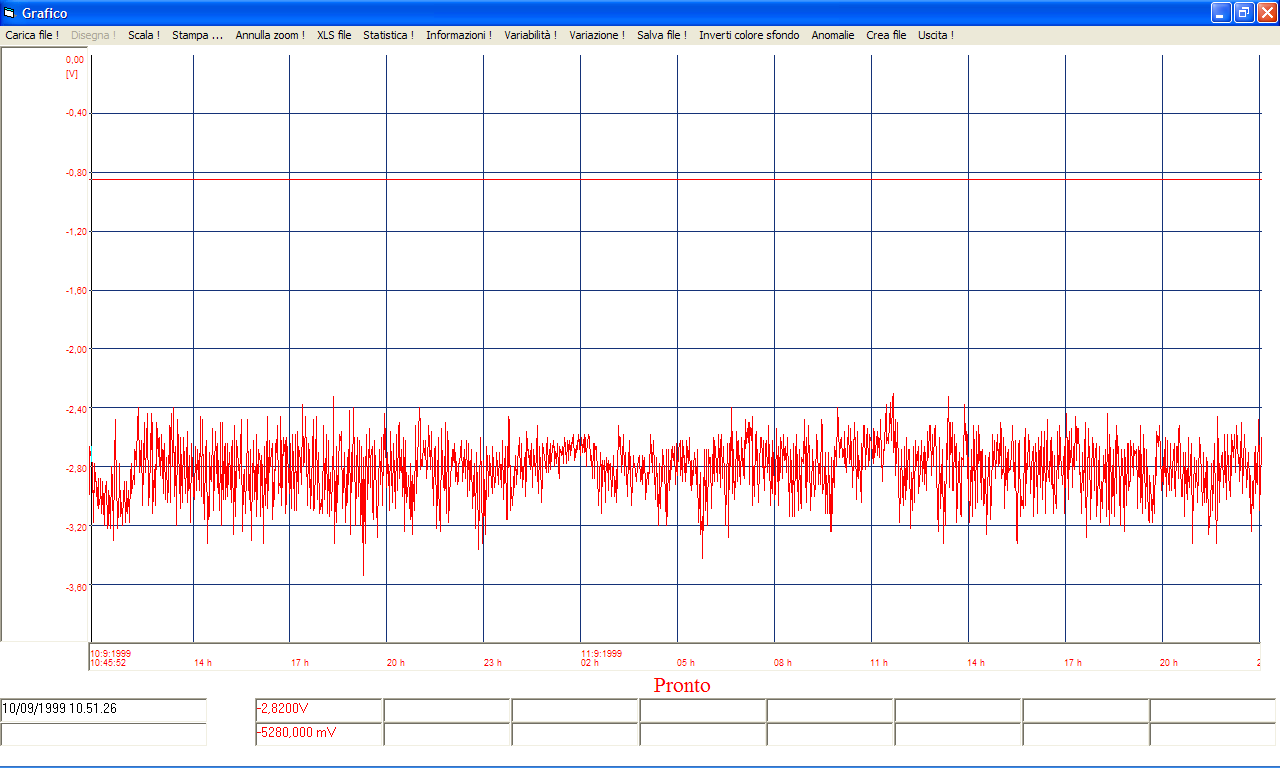

On the basis of our OFFSHORE experience we pointed out a formidable monitoring system for jackets that can be interfaced with standard PC and managed both locally that in remote.

As a completion of the cathodic protection systems supply, we have all the relevant accessories; from cables to test points, from the aluminothermic weldings to the metallurgical backfill.

Service

The same staff of technicians in charge to follow the engineering development and the material production for each job, are available to give all the necessary assistance in site and all over the world (follow up) up to the final test of the systems.

Our established history with a long activity in this field grants the availability of all the spare parts during the time.

We are available for the systems management with a direct intervention in site and also remotely with our remote monitoring system by means of GSM transmitters.

Our technicians certified UNI EN 15257 are able to perform investigations for detection of corrosion phenomena on all types of steel and other metals.